1.i-pet resinisingeniso

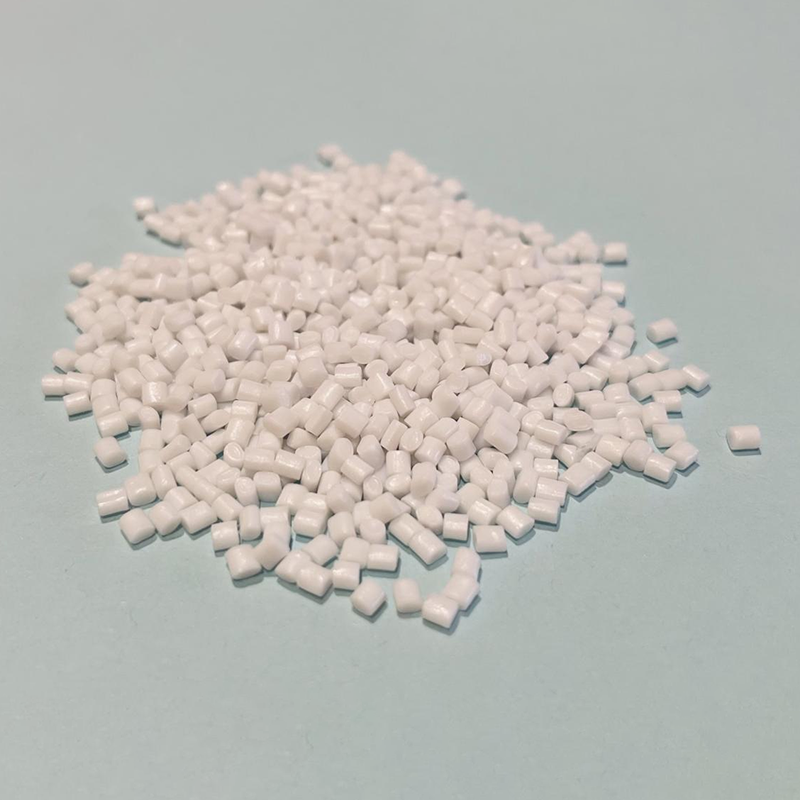

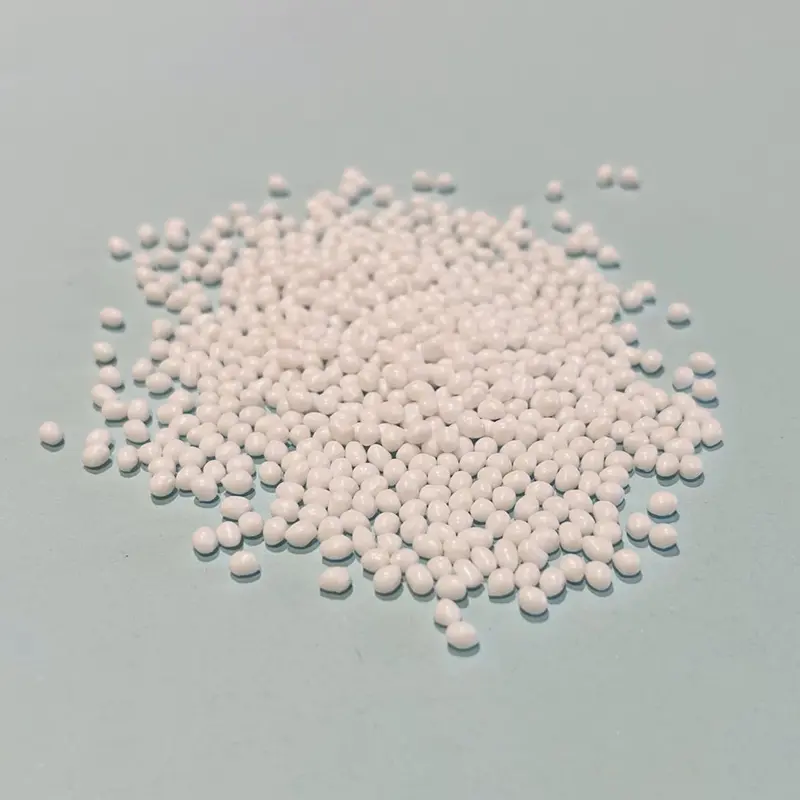

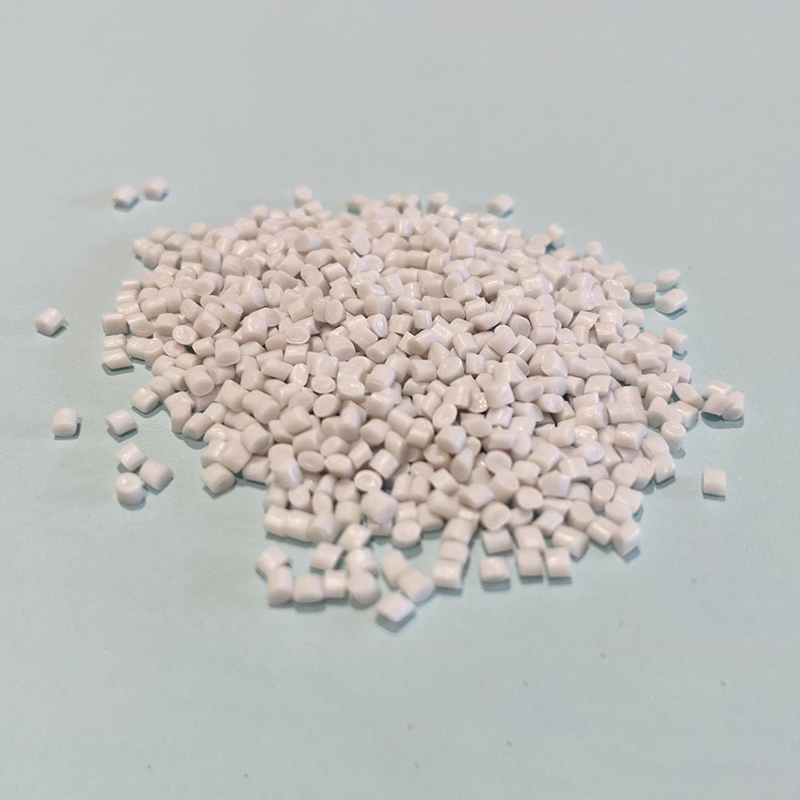

Igama lamakhemikhali e-PET I-Polyethylene terephthalate, eyaziwa nangokuthi i-polyester, ifomula yamakhemikhali COC6H4COOCH2CH2O.I-Dihydroxyethyl terephthalate yalungiswa nge-transesterification ye-dimethyl terephthalate nge-ethylene glycol noma i-esterification ye-terephthalate nge-ethylene glycol, bese kuba ukusabela kwe-polycondensation.Kuyi-crystalline saturated polyester, i-milky emhlophe noma ephuzi ngokukhanyayo, i-polymer ecwebe kakhulu enendawo ebushelelezi futhi ecwebezelayo.Kuyinhlaka evamile empilweni futhi ingahlukaniswa ibe yi-APET, RPET ne-PETG.

I-PET iyi-milky emhlophe noma ephuzi ngokukhanyayo, i-polymer ecwebe kakhulu enendawo ebushelelezi, ecwebezelayo.Inezici ezinhle kakhulu zomzimba nezemishini ebangeni lokushisa elibanzi, izinga lokushisa lokusetshenziswa isikhathi eside lifinyelela ku-120 ℃, ukufakwa kukagesi okuhle kakhulu, ngisho nasezingeni eliphezulu lokushisa kanye nemvamisa ephezulu, izakhiwo zayo zikagesi zisezinhle, kepha ukumelana ne-corona okubi, ukumelana nokukhasa, ukumelana nokukhathala, ukumelana nokungqubuzana, ukuzinza kwe-dimensional kuhle kakhulu.I-PET ine-ester bond, ukubola kuzokwenzeka ngaphansi kwesenzo se-asidi eqinile, i-alkali eqinile ne-steam yamanzi, ukumelana nama-solvents eziphilayo, ukumelana nesimo sezulu esihle.

2.izakhiwo ze-resin

I-PET inokumelana okuhle nokukhasa, ukumelana nokukhathala, ukumelana nokungqubuzana kanye nokuzinza kohlangothi, ukuguga okuncane nobulukhuni obuphakeme, futhi inokuqina okukhulu kakhulu kwe-thermoplastics: ukusebenza kahle kokufakwa kukagesi, ithonya elincane lokushisa, kodwa ukumelana ne-corona okungekuhle.Akuwona ubuthi, ukumelana nesimo sezulu, ukuzinza okuhle kumakhemikhali, ukumuncwa kwamanzi aphansi, ukumelana nama-asidi abuthakathaka nezinyibilikisi zemvelo, kodwa hhayi ukucwiliswa kwamanzi angakwazi ukumelana nokushisa, hhayi ukumelana ne-alkali.

I-PET resininezinga lokushisa eliphezulu lokushintsha kwezingilazi, izinga lokucwebezela kancane, umjikelezo omude wokubumba, umjikelezo omude wokubumba, ukushwabana okukhulu kokubumba, ukuqina okungekuhle kwe-dimensional, ukubumba kwecrystallization okufiphalayo, ukumelana nokushisa okuphansi.

Ngokuthuthukiswa kwama-nucleating agents kanye nama-crystallizing agents kanye ne-glass fiber reinforcement, i-PET inezici ezilandelayo ngaphezu kwezakhiwo ze-PBT.

1. Izinga lokushisa lokushintsha okushisayo kanye nezinga lokushisa lokusetshenziswa kwesikhathi eside liphakeme kakhulu kumapulasitiki obunjiniyela obujwayelekile be-thermoplastic.

2. Ngenxa yokumelana nokushisa okuphezulu, i-PET ethuthukisiwe ifakwe ku-10S ekugezeni kwe-solder ku-250 ° C, cishe ngaphandle kokuguqulwa noma ukuguqulwa kombala, okulungele ngokukhethekile ukulungiswa kwezingxenye ze-elekthronikhi nezikagesi ze-solder welding.

3. Amandla okugoba angu-200MPa, i-elastic modulus ingu-4000MPa, ukumelana nokukhasa nokukhathala nakho kuhle kakhulu, ukuqina kwendawo kuphezulu, kanye nezakhiwo zemishini zifana namapulasitiki e-thermosetting.

4. Njengoba intengo ye-ethylene glycol esetshenziswa ekukhiqizeni i-PET cishe isigamu se-butanediol esetshenziselwa ukukhiqizwa kwe-PBT, i-PET resin kanye ne-PET eqinisiwe iyinani eliphansi kakhulu phakathi kwamapulasitiki obunjiniyela futhi abe nokusebenza kwezindleko eziphezulu.

Ukuthuthukisa izakhiwo ze-PET, i-PET ingaxutshwa ne-PC, i-elastomer, i-PBT, ikilasi le-PS, i-ABS, i-PA.

I-PET (i-PET ethuthukisiwe) icutshungulwa ngokuyinhloko ngokubunjwa komjovo, kanti ezinye izindlela zifaka i-extrusion, i-blow molding, i-coating kanye ne-welding, ukubekwa uphawu, umshini womshini, i-vacuum coating nezinye izindlela zokucubungula zesibili.Yomisa kahle ngaphambi kokwenza.

I-Polyethylene terephthalate ilungiswa nge-transesterification ye-dimethyl terephthalate nge-ethylene glycol noma i-esterification ye-terephthalate nge-ethylene glycol, bese kuba ukusabela kwe-polycondensation.I-polyester egcwele i-crystalline, isilinganiso sesisindo samangqamuzana (2-3) × 104, isilinganiso sesisindo esimaphakathi nenombolo yesisindo samangqamuzana si-1.5-1.8.

Izinga lokushisa lokushintsha kwengilazi lingu-80 ℃, ukumelana nokushisa kukaMartin 80 ℃, izinga lokushisa elishisayo le-thermal deformation 98℃(1.82MPa), izinga lokushisa lokubola lingu-353℃.Inezici ezinhle kakhulu zemishini.Ukuqina okuphezulu.Ukuqina okuphezulu, ukumuncwa kwamanzi amancane, ukuzinza okuhle kwe-dimensional.Ukuqina okuhle, ukumelana nomthelela, ukumelana nokungqubuzana, ukumelana nokukhasa.Ukumelana okuhle kwamakhemikhali, okuncibilika ku-cresol, i-sulfuric acid egxilile, i-nitrobenzene, i-trichloroacetic acid, i-chlorophenol, engancibiliki ku-methanol, i-ethanol, i-acetone, i-alkane.Izinga lokushisa lokusebenza -100 ~ 120 ℃.Amandla okugoba 148-310MPa

Ukumuncwa kwamanzi 0.06%-0.129%

Amandla omthelela 66.1-128J /m

Ubulukhuni be-Rockwell M 90-95

Ubude 1.8%-2.7%

3. ukucubungula ubuchwepheshe

Ukucutshungulwa kwe-PET kungaba ukubumba umjovo, ukukhishwa, ukubunjwa kokushaywa, ukuhlanganisa, ukubopha, ukukhanda imishini, i-electroplating, i-vacuum gold plating, ukuphrinta.Okulandelayo ngokuyinhloko kwethula izinhlobo ezimbili.

1. Isiteji somjovo ① ukulungiselelwa kwezinga lokushisa: umlomo wombhobho: 280~295℃, ngaphambili 270~275℃, ukuganga okuphakathi 265~275℃, ngemva kuka-250-270℃;Isivinini se-screw 50 ~ 100rpm, izinga lokushisa lesikhunta 30 ~ 85 ℃, isikhunta se-amorphous singu-70 ℃, ingcindezi yangemuva 5-15KG.② Isomisi sokucwiliswa komjovo esivivinyweni, izinga lokushisa leshubhu elingu-240 ~ 280 ℃, ingcindezi yomjovo 500 ~ 1400 ℃, izinga lokushisa lomjovo lokubumba 260 ~ 280 ℃, izinga lokushisa lokumisa 120 ~ 140 ℃, thatha amahora angu-2 ~ 5.

2. Esigabeni sefilimu, i-PET resin iyasikwa futhi yomiswe ngaphambili ukuze kuvinjwe i-hydrolysis, bese ishidi eliwugqinsi le-amorphous likhishwa ku-extruder ngo-280 ° C nge-T-mold, bese isigubhu sokupholisa noma isipholile sicinywa. yigcine isesimweni se-amorphous ukuze uthole ukuma okuqinile.Ishidi eliwugqinsi libe seliqondiswa kabili linwetshwa itende ukuze lenze ifilimu ye-PET.

Ukwelula isikhathi eside kuwukushisa ishidi eliwugqinsi libe ngu-86 ~ 87 ℃, futhi kulokhu kushisa, welule izikhathi ezingaba ngu-3 eduze nokuqondisa kwendiza yeshidi eliwugqinsi, ukuze ukuma kwayo kuthuthukise izinga lokucwebezela ukuze kufinyelele izinga lokushisa eliphakeme: the Izinga lokushisa eliguqukayo langaphambi kokushisa elingu-98 ~ 100℃, izinga lokushisa eliqinile lika-100 ~ 120 ℃, isilinganiso sokuqina esingu-2.5 ~ 4.0, kanye nezinga lokushisa elishisayo elingu-230 ~ 240℃.Ifilimu ngemva kokwelula okuqondile nokuvundlile nayo idinga ukufana nokushisa ukuze kuqedwe ukuguqulwa kwefilimu okubangelwa ukwelula nokwenza ifilimu ngokuzinza okuhle kokushisa.

Isikhathi sokuthumela: Sep-05-2023